The electronics industry is under increasing pressure to rethink its environmental footprint. One of the most effective yet overlooked ways to reduce the carbon footprint in electronics lies in the packaging—specifically, the transition from traditional plastic-based solutions to molded fiber packaging.

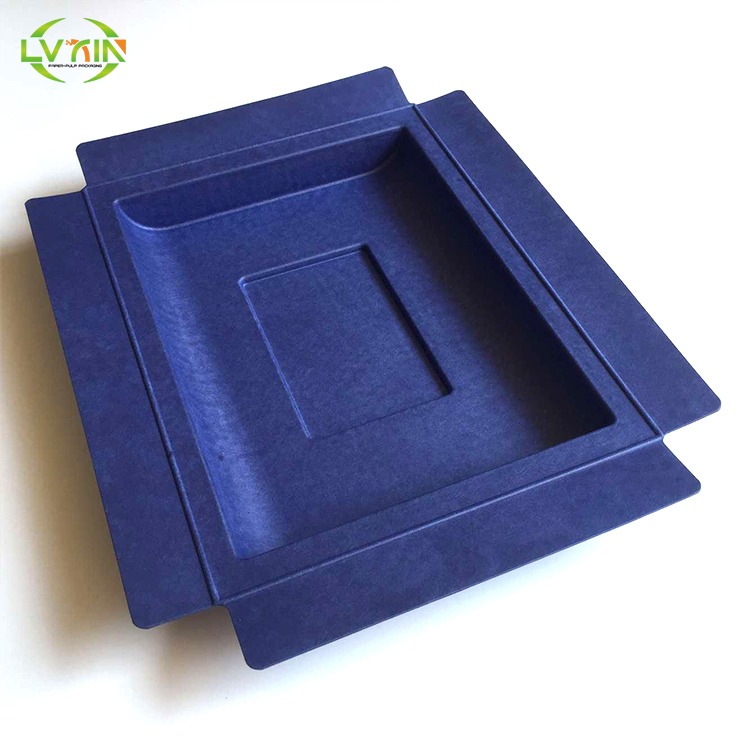

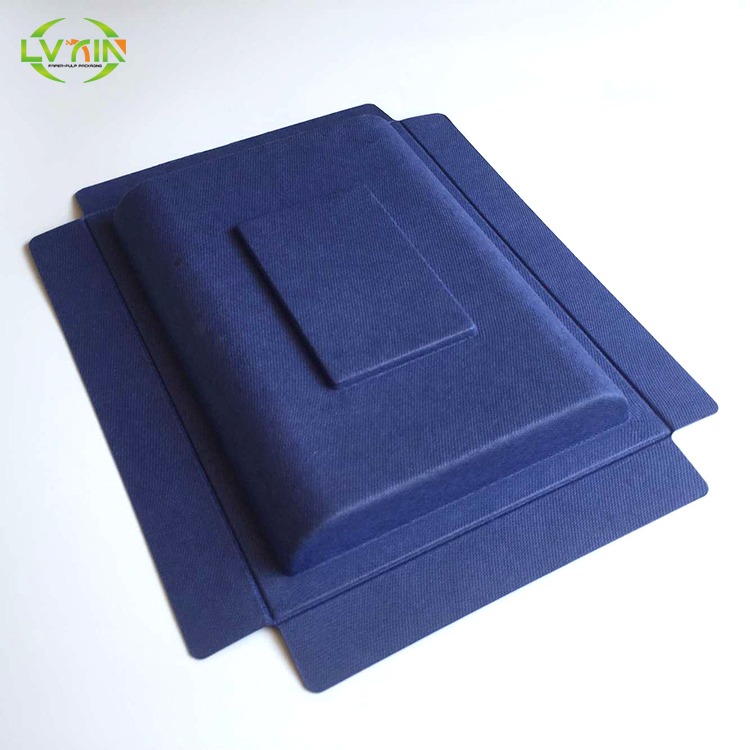

At Lvxin, we specialize in delivering custom molded pulp packaging tailored for electronic products. Our wet-pressed pulp trays not only protect your devices with precision but also support your sustainability goals. In this article, we explore how molded fiber packaging plays a pivotal role in lowering emissions and reshaping the future of eco-conscious electronics.

The Environmental Burden of Traditional Electronics Packaging

From EPS foam and plastic clamshells to multi-layer films, conventional electronics packaging materials are derived from fossil fuels and often end up in landfills or oceans. These materials contribute significantly to global CO₂ emissions, both during production and disposal. According to a 2023 report from the Ellen MacArthur Foundation, packaging accounts for nearly 40% of plastic waste, with electronics packaging being a major contributor. While electronics companies innovate with energy-efficient devices, packaging remains a silent carbon emitter.

Molded Fiber Packaging: A Sustainable Alternative

Molded fiber, or molded pulp, is made from recycled paper or plant-based fibers. It’s fully biodegradable, compostable, and recyclable. Unlike plastics, molded fiber doesn’t release microplastics or toxic chemicals into the environment.

But what makes it especially appealing to electronics brands is its versatility and performance:

-

✅ Excellent cushioning and shock resistance

-

✅ Custom-molded for tight-fit electronic products

-

✅ Smooth surface via wet-press molding for a premium look

-

✅ Low environmental impact across its lifecycle

These features make molded fiber packaging for electronics a smart alternative that balances functionality and responsibility.

How Molded Fiber Packaging Reduces Carbon Footprint

The carbon savings with molded fiber packaging come from multiple angles:

1. Lower Emissions in Raw Material Sourcing

Traditional plastic packaging relies on petrochemicals, which have a high carbon cost. In contrast, molded pulp is made from recycled materials such as paper or bagasse, significantly reducing energy input.

2. Energy-Efficient Manufacturing

Lvxin’s wet-press pulp packaging technology consumes less energy compared to plastic molding or vacuum-forming processes. The integrated drying and pressing systems in our production line minimize resource consumption.

3. Reduced Transportation Emissions

Our fiber trays are often lighter and more compact, optimizing shipping efficiency and reducing fuel-related emissions. This is particularly valuable in global supply chains.

4. End-of-Life Carbon Benefits

Unlike plastic, which persists for centuries, biodegradable molded fiber decomposes naturally, contributing to a circular economy. Composting instead of landfilling reduces methane emissions and supports soil health.

Lvxin's Role in Green Electronics Packaging

At Lvxin, we help electronics brands transition to eco-friendly molded pulp solutions that meet both functional and environmental demands. Whether you're packaging smartphones, headphones, power banks, or PCB components, our custom wet-pressed trays are engineered to deliver performance and sustainability.

Featured Products:

-

Wet-pressed molded fiber tray for smart devices

-

Eco packaging for earbuds and wearable electronics

-

Precision-fit pulp insert for consumer electronics

-

Custom molded pulp tray for battery packs and accessories

Our pulp packaging solutions are fully certified for strength, moisture resistance, and dimensional accuracy, making them ideal for fragile and high-value electronics.

Use Case: Sustainable Packaging for a Consumer Electronics Brand

A recent Lvxin client—an EU-based audio electronics startup—replaced their plastic EVA cases with our custom molded fiber inserts. As a result:

-

Their packaging carbon footprint dropped by 58%

-

Unboxing experience improved due to the premium wet-pressed texture

-

They received favorable attention from eco-conscious retailers

This case underscores how sustainable packaging for consumer electronics isn’t just good for the planet—it’s good for business.

Why Electronics Brands Are Shifting to Molded Pulp

The shift toward eco-friendly electronics packaging is driven by a combination of policy pressure, consumer demand, and brand reputation goals:

ESG compliance and corporate sustainability reporting

Increasing preference for green-labeled products on Amazon & DTC platforms

Reduction in plastic taxes and material levies in the EU and North America

Enhanced brand image and unboxing appeal

By adopting molded fiber packaging, electronics brands can stay ahead of regulatory requirements while building trust with environmentally conscious consumers.

Future Trends in Electronics Packaging Sustainability

Looking forward, several trends will shape the next generation of electronics packaging:

-

Digital packaging lifecycle tracking (via QR/NFC)

-

Zero-plastic packaging mandates for electronics in the EU by 2030

-

Wider use of molded pulp for internal cushioning and external retail display trays

-

Hybrid designs with molded fiber + FSC-certified cardboard sleeves

Lvxin is actively investing in design innovation and scalable production lines to meet these emerging needs and support brand partners worldwide.

Conclusion:

The electronics industry has reached a turning point—one where performance can no longer come at the cost of the planet. By adopting molded fiber packaging, brands not only reduce their carbon footprint but also deliver a message of responsibility, innovation, and future readiness. Lvxin stands at the forefront of this shift, offering sustainable molded pulp packaging solutions tailored to the evolving needs of modern electronics.

Ready to reduce your carbon footprint?

Contact Lvxin for custom molded fiber packaging that protects both your product and the planet.