Sustainability is no longer an optional feature—it’s a necessity. Consumers and businesses alike are demanding environmentally responsible solutions, and recycled dry press molded pulp has emerged as a frontrunner in sustainable packaging materials. Beyond its eco-friendly reputation, there are numerous hidden advantages that make it an indispensable choice for modern brands. Lvxin, a leading molded pulp packaging supplier, has been at the forefront of delivering innovative, high-quality solutions that leverage the full potential of dry press molded pulp.

Why Recycled Dry Press Molded Pulp Matters

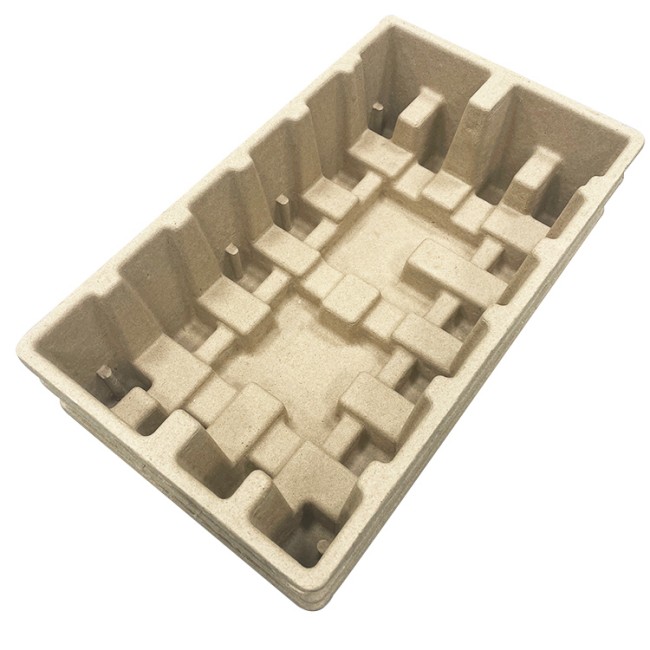

While many people associate molded pulp packaging with simple egg cartons or disposable trays, the material’s applications have evolved dramatically. Dry press molded pulp is produced by pressing recycled fibers into precise, durable shapes without the need for harmful adhesives or plastics. This manufacturing process creates molded pulp trays and packaging products that are not only lightweight and protective but also fully recyclable.

One of the often-overlooked advantages of using recycled dry press molded pulp is its versatility. Unlike traditional packaging materials, molded pulp can be custom-designed to fit virtually any product—electronics, cosmetics, food, and industrial parts. By adopting molded pulp trays, brands can reduce waste, lower transportation costs due to lightweight packaging, and create a premium unboxing experience that resonates with environmentally conscious consumers.

Hidden Advantages You Might Not Know

1. Exceptional Product Protection

Many brands underestimate the protective properties of molded pulp packaging. Dry press molded pulp absorbs shocks and resists compression, keeping fragile products safe during shipping and handling. A well-designed molded pulp tray can perfectly cradle delicate items such as glass bottles, electronics components, or cosmetics, significantly reducing damage rates compared to conventional packaging materials.

2. Customization and Branding Opportunities

Modern molded pulp packaging suppliers like Lvxin offer advanced customization options. Trays and packaging can be tailored to fit products exactly, enhancing display appeal and functional utility. Moreover, branding elements such as embossed logos or textured surfaces can be integrated directly into the tray design, helping companies communicate quality and environmental responsibility simultaneously.

3. Sustainability That Truly Delivers

While recycled packaging is a buzzword, dry press molded pulp lives up to its eco-friendly claims. It is made from post-consumer paper and cardboard, is fully biodegradable, and can be recycled multiple times. By replacing plastic and foam alternatives with molded pulp trays, brands not only reduce their carbon footprint but also appeal to a growing segment of eco-conscious consumers. Sustainability is no longer just a marketing message—it’s a measurable impact.

4. Cost-Effectiveness in the Long Run

Though some businesses initially perceive eco-friendly solutions as more expensive, recycled dry press molded pulp often reduces overall costs. Lightweight yet strong, it lowers shipping expenses while minimizing product damage. Bulk orders of customized molded pulp trays allow companies to benefit from economies of scale without compromising quality or environmental responsibility.

5. Wide Range of Applications

The versatility of dry press molded pulp is one of its most compelling advantages. From protective packaging for electronics to display trays for cosmetics and even food service applications, molded pulp solutions can be tailored to meet specific needs. Lvxin, as a trusted molded pulp packaging supplier, has successfully delivered solutions for diverse industries, demonstrating that this material is far more than a simple tray—it’s a strategic packaging asset.

Lvxin’s Approach to Molded Pulp Innovation

At Lvxin, our philosophy combines sustainability, functionality, and design innovation. Our team works closely with clients to develop molded pulp packaging that not only protects products but also enhances brand perception. By leveraging advanced molding techniques, we create molded pulp trays with precise dimensions, tailored cushioning, and aesthetic finishes, ensuring that every piece aligns with the client’s vision.

We also prioritize sustainability throughout the manufacturing process. Using high-quality recycled fibers and optimizing production to minimize waste, Lvxin ensures that every product contributes positively to a circular economy. For companies seeking both environmental responsibility and high-performance packaging, Lvxin’s dry press molded pulp solutions represent an ideal choice.

Conclusion: The Strategic Advantage of Recycled Dry Press Molded Pulp

Recycled dry press molded pulp is no longer just a green alternative—it is a strategic choice that combines protection, customization, sustainability, and cost-effectiveness. By adopting molded pulp packaging and molded pulp trays from trusted suppliers like Lvxin, brands can elevate product presentation, reduce environmental impact, and enhance operational efficiency.

The hidden advantages of recycled dry press molded pulp make it a forward-thinking solution for businesses committed to sustainability, quality, and consumer satisfaction. In an era where packaging speaks as loudly as the product itself, Lvxin helps brands transform every tray into an opportunity for impact, performance, and brand storytelling.